| Sign In | Join Free | My uabig.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My uabig.com |

|

Brand Name : CHANGTE

Model Number : CT-W013

Certification : ISO9001:2015

Place of Origin : CHINA,HEBEI

MOQ : 1m

Price : 10.5USD/M

Payment Terms : Negotiate with the customer

Supply Ability : 500tons

Delivery Time : 3-7days

Packaging Details : pallte

Material : Steel Wire

Raw Material : 65mn, 70mn, 60steel, 55steel, 45steel

Wire Diameter : 0.5mm to 12mm

Hole opening : Hole opening: 0.5 to 120mm

Type : Mine Sieving Mesh

Hole Type : Square, Slot, Rectangle, Diamond

Hook Type : V Hook, U Hook

Treatment : Anti-Rusty Oil, Anti-Rusty Spray

Surface treatment : anti-rust paint, anti-rust oil

Hs : 73144900

High Tensile Heavy Duty Vibrating Woven Mesh Screen Crimped Mine Sieving Screen Inclined Vibrating Screen Sieve

1. Woven Mesh Screen specification technical data

Screen mesh for vibrating screen is mainly to sifted some exact substances we want with correct sizes. such as in the quarry, to suit the machines equipment, we studied and produced series of high carbon steel vibrating woven screen mesh such as hook type, flat type, diamond self cleaning screen mesh, anti clogging screen mesh. high carbon steel overlooks vibrating woven mesh mainly use the 65Mn or high tensile steel wire etc, which is wear-resisting.

2. Advantages : Heavy Duty Mine Crimped Woven Wire Mesh Screen 12.5MM Diameter

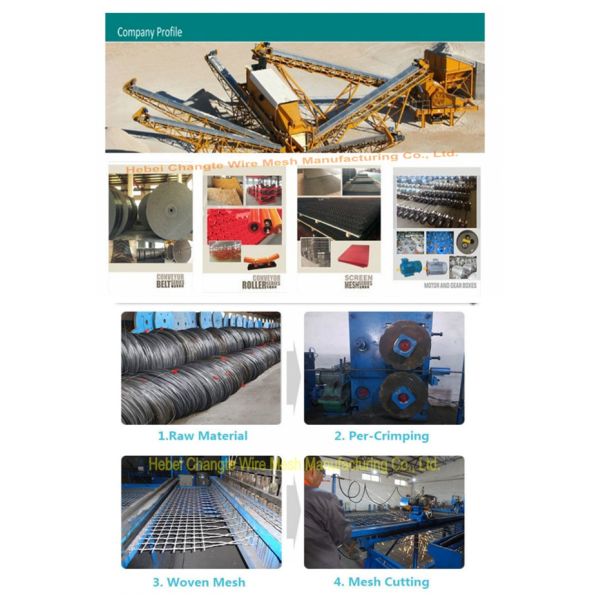

3. Manufacturer:fast delivery, high quality and good price.

4. Delivery: 10 days to 20 days in common.

5. Quality: we have our own stable supplier, who can supply us good quality material and can sure the delivery after place order.

6. Hole type: square, rectangular and long slot. Inherit'>4. Feature: Longer life, High adhesion, excellent efficiency of mechanical splice.

7. Pre-crimped wire mesh is made of wire diameters ranging from 1.5mm to 6 mm. It can be used for windows, partitions, roasting of meat and flour sieving or mine screens.

8. In the pre-crimping process, the wire is first formed (crimped) in precision machines using rotary dies that precisely define the spacing of the wires. This insures that the wires are locked firmly together at the intersections. The pre-crimped wires are then assembled in custom designed screen assembly machines (looms).When the open area is important, extra crimps between the intersections provide a more rigid weave and provide locking and tightness for light wires in relation to the large openings.

9. Due to the crimping process, the mesh have very accurate and consistent openings and are woven after crimping. It is typically preferred for vibrating screens and many other applications where sizing is critical.

| S / | WIRE DIA | OPEN SIZE | |

| 1 | 0.5 | 0.3 | 1200mmx1500mm 1500mmx2000mm 1500mmX2470mm 1600mmX3100mm 1600mmx2550mm 1630mmX2550mm 1750mmx4500mm 1850mmx2070mm 2000mmx3000mm 2030mmX2050mm 2070mmx2470mm ...Can be customized according to customer specified model specifications |

| 2 | 1 | 0.75 | |

| 3 | 1.5 | 1 | |

| 4 | 2 | 1.5 | |

| 5 | 3 | 2 | |

| 6 | 4.0mm | 2.5mm | |

| 7 | 5.0mm | 3mm | |

| 8 | 6.0mm | 3mm | |

| 9 | 7.00mm | 3mm | |

| 10 | 8.0mm | 3mm | |

| 11 | 9.0mm | 3.5mm | |

| 12 | 9.5mm | 3.5mm | |

| 13 | 10.mm | 4mm | |

| 14 | 11.0mm | 4mm | |

| 15 | 12.0mm | 4mm | |

| 16 | 12.5mm | 4mm | |

| 17 | 13.0mm | 4mm | |

| 18 | 14.0mm | 4mm | |

| 19 | 15.0mm | 4mm | |

| 20 | 16.mm | 4mm | |

| 21 | 17.mm | 4.5mm | |

| 22 | 18.mm | 5mm | |

| 23 | 19.mm | 5mm | |

| 24 | 20.0mm | 6mm | |

| 25 | 21.0mm | 6mm | |

| 26 | 22.0mm | 6mm | |

| 27 | 23.0mm | 6mm | |

| 28 | 24.0mm | 6mm | |

| 29 | 25.0mm | 6mm | |

| 30 | 26.0mm | 6mm | |

| 31 | 30.0mm | 6.5mm | |

| 32 | 32.0mm | 7mm | |

| 33 | 35.0mm | 7mm | |

| 34 | 38.0mm | 8mm | |

| 35 | 40.0mm | 8mm | |

| 36 | 45.0mm | 8mm | |

| 37 | 50.0mm | 8mm | |

| 38 | 55.0mm | 8mm | |

| 39 | 60.0mm | 8.5mm | |

| 40 | 65.0mm | 8.5mm | |

| 41 | 75.0mm | 9 mm | |

| 42 | 80.0mm | 9 mm | |

| 43 | 90.0mm | 9mm | |

| 44 | 100.0mm | 10mm |

| Carbon Steel Grades | ||||

| No. | Steel Grade | Chemical Composition (%) | ||

| C | Si | Mn | ||

| 1 | #45 | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 |

| 2 | #50 | 0.47-0.55 | ||

| 3 | #55 | 0.52-0.60 | ||

| 4 | #60 | 0.57-0.65 | ||

| 5 | #65 | 0.62-0.70 | ||

| 6 | #70 | 0.67-0.75 | ||

| 7 | 65Mn | 0.62-0.70 | 0.90-1.20 | |

| 8 | 72A | 0.70-0.75 | 0.15-0.35 | 0.30-0.60 |

| Note: Steel grades #45, #50 and #55 are medium-carbon steel. Steel grades #60, #65, #70, 65Mn and 72A are high carbon steel. | ||||

|

|

Anti Clogging Diamond Hole 72A Steel Woven Mesh Screen Images |